Introduction

Safety fuel tanks since 1994

For more than 20 years, we have been manufacturing explosion-suppressant, self sealing and flame retardant fuel tanks using proprietary technologies developed for specific use in the Automotive, Marine and Aviation industries. Among the years, we have proudly provided ballistic fuel tanks for Presidential Limousines, Head of States, Popes, Magistrates, and Security Forces vehicles. Moreover, our fuel tanks have been used as safety equipment on bank’s Armored cars, Military Off-Road Vehicles, boats and aircrafts too.

Safety fuel tanks Features:

- NON-EXPLODING

- In Compliance With MIL-T-5578

- Self-Sealing

- Flame Retardant

- Certified By Beschussaamt Ulm In Germany And By U.T.T. In Santa Severa, Italy

- Self Sealing Treatment Keeping Original Applications And

- Less Than 3% Of Fuel Capacity Reduction

- Various Treatments Available Following Customer Needs

or use our contact us form.

or use our contact us form. Treatment / Technology

Self-sealing treatment

This is a feature that, in the event of fire, avoids dangerous fuel leakage. It has been developed to seal bullet entry and exit points, but also any leakage caused by fragments at the moment of impact.

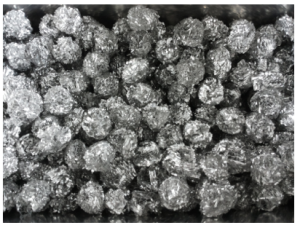

Anti-explosion treatment

Treatment obtained by filling the fuel tank with polyurethane foam (MIL-DTL-83054C) or aluminum spheres, known by the name EXCO or DETO-STOP. Filling with the explosion suppressant material does not alter or affect the draught of the fuel.

Anti-grenade protection

The application of additional layers of composite material of aramid origin guarantees additional protection even in the case of hand grenades.

Flame-retardant protection

This is a feature obtained through the use of specific resins on the outer surface of the fuel tank, loaded with special flame-retardant materials. The resistance obtained through this application can allow exposure to fire for over seven minutes.

Combinations of treatment

Starting from the standard fuel tanks made by OEMs, we are able to provide different levels of protection. Therefore, our customers can ask for a single protection treatment, combine several treatments, or request comprehensive protection using all the treatments in the catalogue. The fuel tank, once treated, will last as long as the original fuel tank.

For Armored Vehicles

Safety First!

This proprietary technology is developed by our principal company M.E.RIN in Italy. With over 20 years in the production of M.E.RIN self-sealing fuel tanks, guarantees the armoring protection of our customers’ vehicles against bullets of up to 7.62 AP caliber. Various treatments are available, which can be applied individually or according to the STANAG specifications and as requested by the customers.

While driving the vehicle, you make sure that all components are complying the contract requirement but do you imagine that what will happen in the event of fuel tank on fire and explode? You cannot just protect the fuel tank with mild steel or ballistic steel plate but you must have to use a safety treated fuel tank with self-sealing, anti-grenade, anti-explosion and safe from fire hazards. This is really important to use a very secured fuel tank in armored vehicles. We have a wide range to offer fuel tanks for your vehicles. You have to select the treatment and we will offer you a certified fuel tank securing you from life threating risks.

For Motor Sports

For Motor Sports

Car racing is really exciting and very enjoying Motorsports. When it comes to safety, the major component to secure is fuel tank. For motorsports vehicles weather cars, motorcycles or trucks, we have our proprietary technology to secure the fuel tank from fire and explosion caused by fuel tank leakage and catching fire. Keeping the driver safe from fire risk is our challenge. We do have various options for motorsports sector. We are the major vendor for safety fuel tanks for some of the very famous motorsports events in the world. We would like to extend our support to all of motorsports drivers to keep them safe from potential risks caused by fuel tanks leakage and catching fire.

For Marine Use

We have designed and produced flexible fuel tanks for below the deck installations. Flexible fuel tanks are particularly suitable for offshore boats and pleasure craft, as they guarantee easy maintenance and cleaning of the housing compartment. We can assist OEMs during the design phase of new boats, and replace old aluminum or fiberglass fuel tanks with new flexible ones from our side. Specially for Army boats and the boats use by Coast Guards we can ensure the safety using our treated fuel tanks. The fuel tanks are supplied complete with all accessories and ready to install. Lastly, they can hold any type of fuel including the most aggressive containing 100% ethanol. The luxury yachts also need attention to use our safety fuel tanks for a very safe and secure oceans trips. We can supply all necessary accessories for these fuel tanks installations.

For Aviation Use

The measure task is safety in-flight and during landing. We make complete fuel systems with flexible, anti-explosion and anti-slosh fuel tanks, which can be installed on all types of aircrafts from ultralights and UAVs, and to certified helicopters and passenger planes. Over the years, our business has mainly specialized in the production of fuel tanks for ultralights (ULMs – Ultra-Léger Motorisé), UAVs (Unmanned aerial vehicles) and RUASs (Rotorcraft Unmanned Aerial Systems). Our flexible custom-made fuel tanks with explosion suppressant and anti-slosh foam can be installed on all types of aircraft, from ultralights and UAVs, to helicopters and certified passenger planes. Why do qualified and structured companies or ultralight owners prefer the safety of a flexible fuel tank? Please note below:

TRADITIONAL SYSTEMS

Fuel tanks for ultralight aircraft have traditionally been manufactured with the following materials:

- Welded Light Alloy Sheet

- Fiberglass Or Other Components Or, They Have Been Obtained Directly From Inside The Wings (Wet Wing Systems)

These solutions while economical, present considerable safety concerns:

- Poor Resistance To Vibrations And Pressure Stress

- Corrosion

- Flammability And/or Explosion In Accidental Cases

- Osmosis Through The Fibers

Now consider below points with our treated fuel tanks:

- Welded Light Alloy Sheet

- Fiberglass Or Other Components Or, They Have Been Obtained Directly From Inside The Wings (Wet Wing Systems)

These solutions while economical, present considerable safety concerns:

THE SAFE CHOICE YOU CAN COUNT ON

TECNICAL FEATURES:

- Nylon Fabric With Nitrile Rubber Coating

- Tensile Strength Of The Fuel Tank Wall

- Tensile Strength Of The Joints

- Resistance To Tearing

- Perforation Resistance

- Resistance To Dropping

- Anti-Explosion And Impact/Drop Test

- Ultralight Weight Materials

- Resistance To Stress Caused By Flight (Anti-Slosh)

- Installation And Maintenance Processes Are Notably Facilitated

The conclusion is to adapt this high technology in aviation industry fuel tanks. Our proprietary technology will be with you during flights to ensure safety against risks from fuel tanks.

If you have a question which has not been answered here, or you have other inquiries please email at

For Industrial Sector

We have been producing solutions for power transformers since 1994.

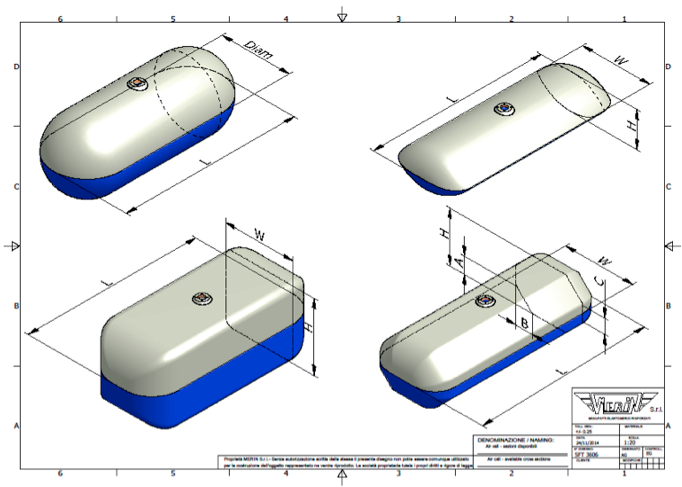

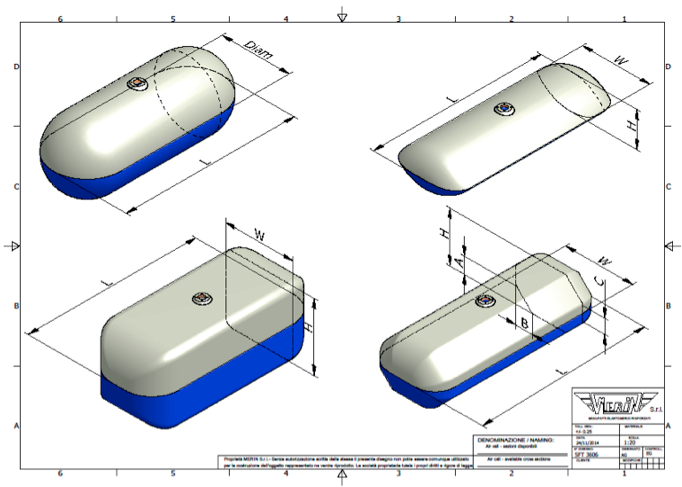

With our proprietary technology, you can avail the benefits of our custom-made Air-Cells, or choose from the range of standard options – the closest Air-Cell to your needs. Our developed Air-Cell products have been specifically made of flexible rubber fabric for the power transformer industry. Our Air-Cells are designed for cylindrical, elliptical, octagonal or rectangular-shaped conservators. Once installed inside the conservator, they adapt by contracting or expanding thanks to the vent on the flange, thus compensating for the displacement of oil caused by the temperature variations of the transformer.

AIR CELL DESIGN: what we need…

- Dimensions When Flat A X B Position Of The Flange (Exact Measurements)

- Orientation Of The Flange (Relative To The Holes)

- Position Of Anchoring Handles

- Preferred Connection Type For Venting

Our designed Air-Cell also acts as a barrier to separate undesirable elements in the atmosphere, such as water vapor, nitrogen, ozone and oxygen, fine dusts and smog, from the transformer oil within a conservator.

In addition, this barrier offers the following features:

- Easy Maintenance

- Extended Service Life

- Prevention Of Corrosion

- Oil Can Be Filled Into The Transformer Tank Without Being Exposed To The Air

- Since Insulating Oil Is Completely Isolated From The Atmosphere By An Air Cell, There Is No Possibility Of Oxygen Or Moisture Penetrating The Oil

- Pressure On The Surface Of The Oil Is Constantly Maintained At The Atmospheric Pressure,Offering No Possibility Of The Oil Becoming Supersaturated And Forming Bubbles; Thus, High Dielectric Strength Can Be Maintained

Certifications

M.E.RIN is an ISO 9001 and UNI/EN 9100 certified company for the aerospace and defense industries. Every year the quality system is tested and updated, as necessary, according to the company’s new requirements. Below you can download the certificate that attests to its regularity and validity.

M.E.RIN fuel tanks have passed all the tests set by the International Automobile Federation. In fact, our company has received all FIA homologations for standards FT3, FT3.5 and FT5-1999.

Buying Procedure

Starting from the standard fuel tanks made by OEMs, we are able to provide different levels of protection. Therefore, our customers can ask for a single protection treatment, combine several treatments, or request comprehensive protection using all the treatments in the catalogue. The fuel tank, once treated, will last as long as the original fuel tank.

- Identify Your Requirement For Armored, Marine Or Aviation Use

- Select Required Treatments

- Confirm Your Order And Register Your Order With Us With Payment

- Supply Us Your Existing Fuel Tank Or Order Us To Buy A Fuel Tank For You

- We’ll Treat The Fuel Tank With Requested Treatment(S)

- Once Your Fuel Tank Ready After Treatment, We Will Return You The Fuel Tank

- You Will Get Use And Maintenance Manual Together With The Treated Fuel Tank

Pictures Gallery

Get a Quote

Kindly send your requirement with specs and quantities you are looking for. Please specify what treatments you want for your vehicle / boat / airplane / industrial tanks. KANAS will supply you competitive prices with good quality products. We supply spare parts as well to support our clients.

Terms and Conditions

Please forward us your requirements and we’ll supply you quotations with product specifications. Terms and conditions are mentioned on our quotes. All payments are required in advance wire transfer to KANAS bank account.