Applications

KANAS manufactures its glasses for armored vehicles and buildings. Our ballistic glasses are widely used in armored vehicles from level BR4 to level BR7 protection and STANAG I, II, III and IV levels. We are providing flat glasses for high-risk facilities such as for Governmental buildings, Embassies/Consulates, Banks/Money Exchanges, armed forces and security agencies. Our production people have multiple years of experience to produce best optical quality and finishing of the ballistic glasses. For high rise building we can supply laminated sandwich glasses as well.

- Military Applications

- Homeland Security Projects

- Law Enforcement & Government Buildings

- Court Rooms & Judge’s Chambers

- Embassy & Consulate Buildings

- Armored Vehicles (APCs / MRAPs / VIP SUVs), Helicopters, Army Boats And Ships

- Safe / Panic Rooms / Bunkers

- Banking Sites / Cash Collection Centers / ATM Machines

Please ask us for clients’ list and you will be impressed that we have so many valuable customers using our ballistic glasses across Middle East / GCC and Asian countries. Now we have started supplying glasses to African region and soon we will also set up a local warehouse facility to cater various demands. We are looking for a local trust worthy partner who can work with us more closely on Ballistic Glasses requirements.

or use our contact us form.

or use our contact us form. Glass Factory

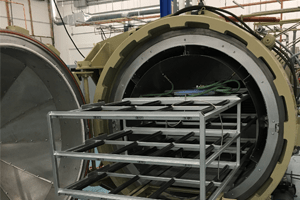

Some of the pictures of our glass factory:

Float Glasses Stocks / Glass Cutting / Glasses Grinding / Clean Room / Glasses Lamination / Autoclave / Glass Bending / Glass Inspection / QC / Ready glasses for delivery

These pictures are for illustrations. We invite our customers to visit our factory and see actual glass making process but due to confidentiality of manufacturing process, we do not allow taking photos or making movies of our factory production areas. Any technical questions, we can answer to our valuable customers. We can also print logo our customers together with serial numbers. Serial numbers are a must to track glasses.

Production Process

KANAS manufactures multi-laminated ballistic and safety glass for different types of vehicle models, marine (ships and boats) and for high risk facilities such as Banks, Police Stations, Military buildings, Presidential and governmental buildings and VVIP stages/rostrums, etc.

Our ballistic glasses are manufactured in the supervision of our qualified technicians, using all raw materials from reputed international suppliers. The buying of raw materials and production process are closely supervised to gain the highest quality of glasses. KANAS Ballistic Glass comes in curve and flat and we can produce any design of your need.

It is very important to produce multi-laminated glasses as much transparent as a regular single glass and at the same time to ensure that its protection level is integrated. KANS glass has now become industry standard in its design, clarity, safety and high quality finishing

Bending to OEM Curvature

A minimum tolerance is required while bending the curve windscreens and curve door glasses. Our computerized bending furnaces gives accurate curvature with no distortion at all. There are some special techniques to follow to achieve almost no distortion in the glasses. We have done large and curved windscreens at present in use of various customers for buses and coasters.

Edge Finishing

Edge sealing plays very important role to stop the de-lamination of multi-laminated glasses. The UV rays make harmful effects for PU and PC if the edge seal is not good and properly in place. Air bubble is also formed by the passage of time if the edge sealing is not according to international standards. KANAS use American edge sealing in its production which gives high quality and durability. For low level protection glass we do not need to use polycarbonate. For higher protection levels, we use polycarbonate because in hot weather conditions if polycarbonate is not used then low thickness without polycarbonate is not able to stop the bullets. We can achieve customer requirement on thicknesses requests for specific protection levels. Glass manufacturing is based on multi-layer glass structures with various materials between the glasses. Glass constructions could be different as per threat and multi-glass total thickness requirement.

Anti-Scratch Film

KANAS always use anti-scratch film before making deliveries. It helps to protect the polycarbonate to scratch out during installation.

AUTOCLAVE

To get the best optical quality and durability you again need here a controlled operating autoclave with its software to control the laminated sandwich packages of multilayer glasses with balance heat and pressure. Process starts with de-airing the cold air inside the glass sandwich. Heat rising with air pressure must be controlled with software otherwise you will suffer air bubbles and de-lamination as well. Glass and PC must heat up and cool down equally. The extended warranty depends on this autoclave process on the glasses. Our production managers do understand and deliver right excellent jobs.

OPTICAL QUALITY

After autoclave process we go through optical tests to ensure the delivery of glasses without optical distortion. Visibility from glass surface will be thoroughly checked and that quality is achieved during the process of lamination of glass layers with PC-polycarbonate during the autoclave process. And thus during ride, passenger eyes do not see distortion or waves in the glass while sitting in an armored vehicle

DELIVERY

All BR Glasses KANAS offers, are always double-checked with the provided specifications and assessed by industry experts in our team to conclude the right product / solution fulfilling your need. Glasses are packed ensuring air and sea worthy packing. Completely covered with plywood and strong frame gives glasses a secured and safe transportation. Glasses packed in wooden boxes can be easily picked up by forklifts and very large boxes by crane.

TECHNICAL HELP CENTER

KANAS proudly offers its Technical Help Center for any kind of help required to install / design the glasses as per the client’s requirement. Any help at our place in UAE will be free of cost. We also offer installation at client site at reasonable price. e.

Protection Levels

Ballistic glasses come in curve and flat. Levels of protection are BR4, BR5, BR6, BR7, BR7+ and STANAG 2, 3, 4 levels and even higher protection level. We can make customized glasses as well

Chart of protection levels:

Design

Ballistic Glass Design:

There are different designs of armored vehicles presently in the market with various armoring companies. KANAS can manufacturer any of the designs of your needs. We have mostly all the drawings and molds available for the presently required designs in the AV industry even in case if you require a special design then in very less time KANAS can produce your required design glasses. We have automatic CNC machines and all latest equipment in our factory enabling us professional and competent manufacturing process. We can shape your idea in the best presentable and applicable form whether its curve or flat glass.

Optics Clarity

Clarity of Ballistic Glasses:

KANAS claims that its glasses are optically very clear and there is no hazy view for the driver and passengers. Most of the times specially the windscreen has distortion which gives very bad impact on vision. We do a lot of care while the process of lamination of the glass layers and the polycarbonate during the autoclave process, but the most important key point is to give best optical quality on the glass surface; without optical distortion and waviness. Please see our segment of Glass Manufacturing Process for more details.

Durability

Durability comes when the Edge Finishing is superb. Use of raw materials and manufacturing process are all critically important for glass durability.

We have special process and recipe of our ballistic glass production. Our autoclaving and bending processes are always carefully observed and handled by highly experienced production supervisor so there is no chance of de-lamination or distortion. We give standard warranties and we can assure that our ballistic glasses are good for longer period than the offered standard warranty period. We can make glasses for extreme weather conditions to resist temperature ranges +70 degree centigrade to -50 degrees centigrade. Military organizations have been tested our glasses by heating and by freezing before shooting tests.

Certifications

Our glass production factory is ISO certified and adheres to the ISO policies and procedures in order to maintain our quality control standards and promote continuous improvement..

All our glasses tested by well known laboratories.

We always encourage our clients to test our glasses before placing large quantities orders. Samples can be made as per required protection level for shooting test and fitment test.

Pictures Gallery

KANAS Ballistic Glasses

KANAS ballistic glasses are tested, qualified and certified with high quality and with clear visibility.

We manufacture ballistic and special safety glazing for different types of vehicle models, marine use, light weight ballistic glasses for airplanes / helicopters, flat glasses for high risk facilities and different other industrial commercial sectors.

Every year we do inspections of our quality management system to ensure the same best quality and to make any possible improvements in production processes. We also invite our customers to inspect the production of glasses for any of their input. All production is quality approved by ISO.

Our glasses can tolerate extreme weather conditions in high and low range temperatures. Our glasses are tested by various military production teams by freezing and heating the glasses before shooting tests and we are successful for such critical testing.

We always ask our customers to test our glasses in every aspect before giving us large quantity orders for the better satisfaction of end users. Although our glasses are tested and qualified. Vehicles equipped with our ballistic glass are operational in all kind of environments whether deserts or mountains in high and low temperature areas and we have very satisfied customers across the world that confirms our excellent ballistic glass performance. We are ready to serve your any size of orders. Our production process is fast enough to serve your large quantities orders.

To stop de-lamination, we make our glasses with a combination of multiple glass layers, polycarbonate and the seals are of cutting edge technology to stop delamination.

There are success stories where the vehicles equipped with our glasses withstand blasts and severe accidents by saving passengers lives.

20+ years’ experience of our production people enabled us to produce high quality glasses.

Our extra clear best optical quality and high finish are the part of any application of ballistic glasses.

Get a quote

Tell us about your current requirement:

To receive our price quotes, tell us about your current requirement, including product type, protection level, final application, the quantity you’d like to buy, and your contact details. Your requirement will be sent to the concerned person/department and same day you will get a reply. You will receive a customized quote of your request / requirement at our soonest. Most of the available vehicle model prices are ready to put them in an offer or just a phone call away. Flat glasses rates are also readily available for any protection levels.

Warranty

We offer 2 years warranty for manufacturing defects.

Glass warranty can be extended to 3-10 years subject to final application and protection levels.

Terms and Conditions

KANAS is now maintaining stocks in UAE for regular designs. We can ship your order on 100% advance payment and on receipt of your purchase order. Any approvals from local authorities/destination countries are the responsibility of the buyer. We will only ship the glasses on receipt of clients purchase order and verifying documents and it is subject to the approvals if required. Please study our terms and conditions mentioned in our all quotes and invoices.

Downloadable Files

Introduction

Ballistic Glass (Made in UAE)

- Military Applications

- Homeland Security Projects

- Law Enforcement & Government Buildings

- Court Rooms & Judge’s Chambers

- Embassy & Consulate Buildings

- Vehicles, Helicopters And Sea Vessels

- Safe / Panic Rooms / Bunkers

- Banking Sites / Cash Collection Centers / ATM Machines